Description

Product Overview & Definition

Pre glued lashes represent an evolution in false eyelash technology, featuring factory-applied adhesive directly integrated into the lash band structure. This manufacturing approach eliminates the traditional requirement for separate adhesive products, streamlining the application process while maintaining professional-grade performance standards.

The adhesive layer is precision-applied during manufacturing, creating a consistent bond interface across the entire lash band. This construction method differs fundamentally from conventional strip lashes that require manual adhesive application before each use.

Key Features & Specifications

Construction Architecture

The pre glued eyelashes utilize a multi-layer band construction where the adhesive component is integrated as a distinct layer between the lash fiber base and the contact surface. This architectural approach ensures uniform adhesive distribution and controlled bond strength characteristics.

Application Methodology

The installation process involves direct placement of the lash strip onto the natural lash line without intermediate adhesive preparation steps. The pre-applied adhesive activates through pressure and body heat, forming the attachment bond within seconds of contact.

Performance Parameters

Standard pre glue eyelashes are engineered for single-day wear cycles, though specialized cluster variants can maintain adhesion for extended periods of 3-7 days under optimal conditions. Hold duration varies based on environmental factors, skin chemistry, and maintenance protocols.

Material & Quality Standards

Becoda Lash manufactures pre glued lash products using multiple fiber technologies to address diverse market requirements:

Mink Fiber Construction: Natural protein-based fibers offering superior softness characteristics and authentic texture profiles. These materials provide lightweight wear with natural movement patterns.

Silk Fiber Systems: Semi-synthetic fibers engineered for enhanced durability while maintaining flexibility. Silk-based constructions offer consistent curl retention and resilience to environmental humidity.

Advanced PBT Technology: Polybutylene terephthalate fibers represent the premium synthetic category, featuring superior shape memory, heat resistance up to 180°C, and long-term curl stability. PBT construction eliminates organic material concerns while delivering professional-grade performance.

Adhesive Composition Standards

Manufacturing protocols specify hypoallergenic adhesive formulations that minimize sensitization risk. The adhesive chemistry is optimized for biocompatibility while maintaining necessary bond strength parameters for reliable all-day wear.

Technical Specifications Table

| Parameter | Specification |

|---|---|

| Band Width | 0.5-1.0mm |

| Adhesive Layer Thickness | 0.1-0.3mm |

| Fiber Material Options | Mink, Silk, PBT |

| Adhesive Cure Time | 3-5 seconds |

| Standard Wear Duration | 8-12 hours |

| Extended Wear (Clusters) | 3-7 days |

| Bond Strength | 0.8-1.2 N/cm |

| Operating Temperature | 15-35°C |

| Humidity Tolerance | 40-70% RH |

OEM/ODM Services at Becoda Lash

As a professional lash manufacturer, Becoda Lash provides comprehensive original equipment and design manufacturing services for pre glued lash products. Custom development capabilities include:

Formulation Customization: Development of proprietary adhesive formulations tailored to specific hold duration, removal characteristics, or hypoallergenic requirements.

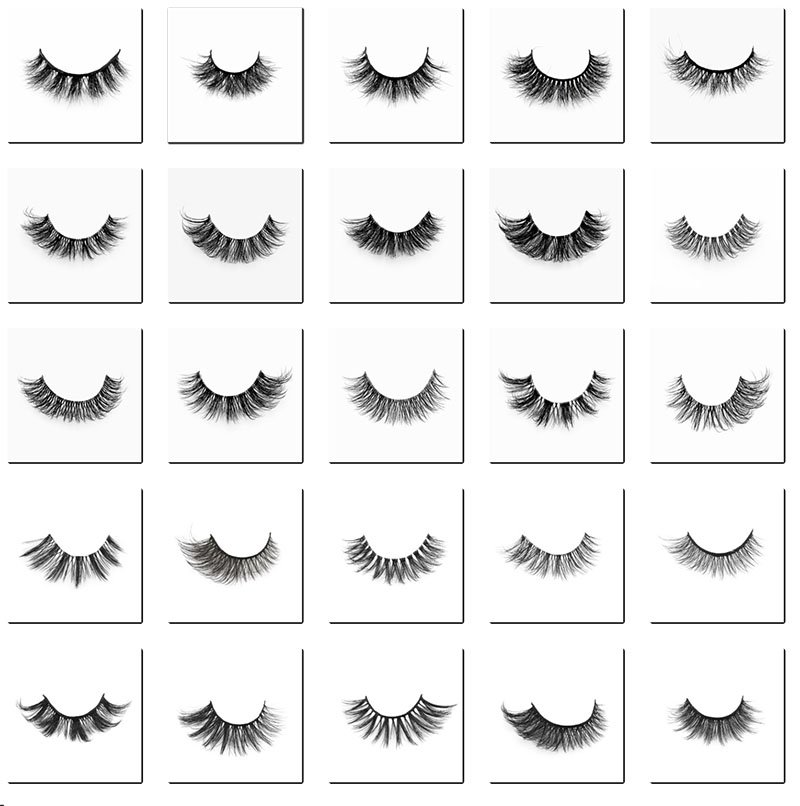

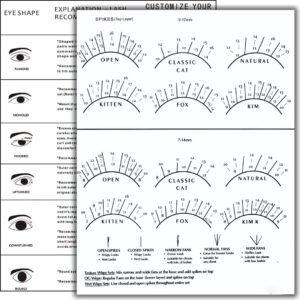

Design Engineering: Custom lash patterns, curl specifications, length gradations, and band configurations engineered to client specifications.

Material Selection: Access to the full range of fiber technologies including mink, silk, and PBT systems with custom blend options.

Packaging Integration: Complete packaging design and production including custom printing, materials selection, and regulatory compliance documentation.

Quality Assurance & Certifications

Manufacturing operations adhere to stringent quality control protocols throughout the production cycle. Each batch undergoes systematic testing including:

- Adhesive bond strength verification

- Fiber attachment integrity assessment

- Curl retention testing under environmental stress

- Hypoallergenic certification through independent dermatological evaluation

- Sterility validation for medical-grade applications

Production facilities maintain ISO quality management system certifications, ensuring consistent manufacturing standards and traceability throughout the supply chain.

Packaging & Private Label Options

Becoda Lash offers flexible packaging solutions for best pre glued eyelashes product lines:

Retail Packaging: Consumer-ready packaging with custom branding, application instructions, and compliance labeling integrated into design specifications.

Bulk Packaging: Professional-grade packaging optimized for salon and distributor requirements, available in various quantity configurations.

Private Label Programs: Complete brand development services including packaging design, regulatory documentation, and market positioning strategy support.

Wholesale Pre Glued Lashes from Becoda Lash

Wholesale programs provide volume pricing structures for distributors, salon chains, and retail partners. Minimum order quantities are structured to accommodate both established retailers and emerging brands entering the market.

The wholesale framework includes:

- Tiered pricing based on volume commitments

- Flexible SKU configurations across style and material categories

- Technical support and training resources for retail staff

- Marketing collateral and product education materials

- Rapid fulfillment protocols for inventory replenishment

Technical Considerations for Optimal Performance

Storage Requirements

Pre glued lash products require controlled storage conditions to maintain adhesive performance characteristics. Recommended storage parameters include temperature ranges of 15-25°C and relative humidity below 60%. Extended exposure to elevated temperatures or humidity can compromise adhesive bond strength.

Application Surface Preparation

Optimal adhesion requires clean, oil-free application surfaces. Natural lash preparation should include gentle cleansing to remove sebum, cosmetic residues, or skincare products that may interfere with bond formation.

Removal Protocols

Safe removal requires oil-based makeup remover or specialized lash adhesive removers applied to soften the adhesive bond before gentle peeling. Forcing removal without proper adhesive dissolution can stress natural lashes.

Market Positioning and Use Cases

Best pre glued lash clusters have gained particular prominence in several application categories:

Travel and On-the-Go Beauty: The compact, self-contained nature makes these products ideal for travel kits and rapid beauty enhancement scenarios.

Beginner-Friendly Options: Reduced technical barriers lower the entry threshold for consumers new to false lash products.

Sensitive Eye Applications: Hypoallergenic formulations address concerns for users with reactive skin or eyes who experience difficulties with traditional lash adhesives.

Quick Event Preparation: Professional applications where time efficiency is critical benefit from the immediate readiness of pre-applied adhesive systems.

Conclusion

Pre glued lashes represent a significant advancement in false eyelash technology, combining manufacturing precision with user-friendly application characteristics. As a professional lash manufacturer, Becoda Lash brings extensive expertise in fiber technology, adhesive chemistry, and quality manufacturing to deliver reliable, high-performance products for both consumer and professional markets.

The integration of advanced materials like PBT fibers with optimized adhesive formulations creates products that meet demanding performance standards while maintaining safety and comfort parameters. Whether for retail distribution, salon professional use, or private label brand development, Becoda Lash’s manufacturing capabilities and OEM/ODM services provide comprehensive solutions across the pre glued lash category.

Pre Glued lashes ST295

Pre Glued Lashes-Discover professional pre glued lashes from Becoda Lash. Advanced adhesive technology, premium materials, OEM/ODM services. Wholesale options available.

Product Brand: Becoda Lash

4.99

Pros

- Pre glued lashes from Becoda Lash feature factory-applied adhesive integrated directly into the lash band, eliminating the need for separate adhesive products. Available in mink, silk, and advanced PBT fiber constructions, these lashes offer streamlined application with professional-grade performance.

Reviews

There are no reviews yet.