Na Becoda Lash, a nossa experiência em tecnologia de pestanas impulsiona o futuro do fabrico de pestanas postiças. Descubra os nossos materiais avançados e as suas características únicas, explore os nossos processos de produção de precisão e compreenda o nosso rigoroso sistema de controlo de qualidade. Junte-se a nós para soluções de pestanas inovadoras e superiores.

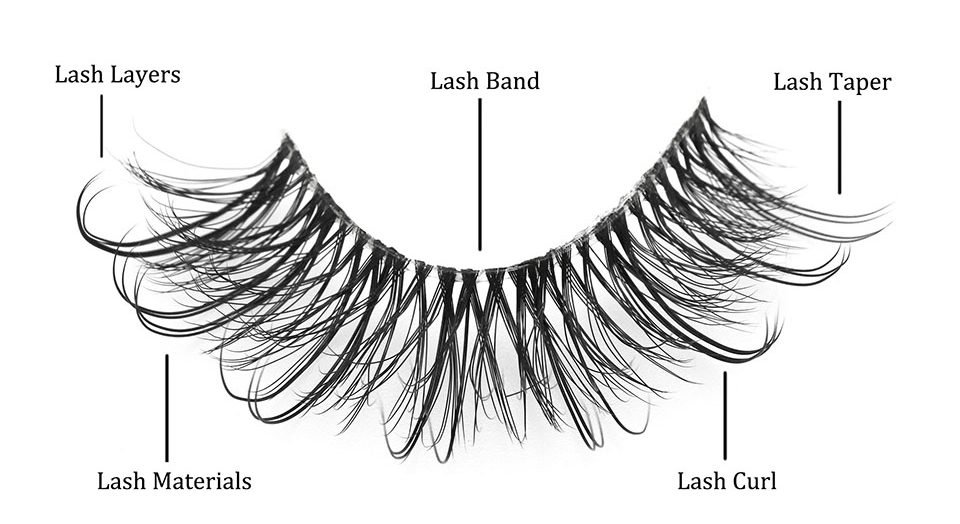

Lash Tech :The Anatomy of an Becoda Eyelash

This section delves into the foundational elements that define a superior false eyelash. From the selection of premium raw materials to the precise engineering of thickness and curl, every detail is meticulously considered. Explore the core components and understand the language of professional lash technology.

Lash Tech :Becoda Lash Materials & CharacteristicsLash Tech

what we do

Raw Material Fibers: The Foundation of Quality

At Becoda Lash, we use only the finest raw materials to craft our premium eyelash extensions. Each material is carefully selected for its unique properties, ensuring comfort, durability, and stunning aesthetics. We prioritize high-quality, sustainable, and ethical sourcing to deliver products that meet the highest industry standards.

Mink Materials

Made from genuine mink fur, offering an incredibly soft, lightweight, and natural feel. They provide a luxurious, wispy appearance that mimics natural lashes.

Advanced PBT

A high-grade synthetic polymer known for its durability, excellent curl retention, and consistent quality. It's lightweight, flexible, and can be crafted to various textures, making it a versatile and hypoallergenic option.

Silk Materials

Our proprietary silk fibers are designed for a rich, deep black color with a beautiful satin sheen. They are lightweight, flexible, and create a fuller, more glamorous look while maintaining comfort.

Cashmere Materials

Exclusive to Becoda Lash, these ultra-fine fibers are exceptionally soft and lightweight, providing a matte finish and superior comfort. They are perfect for achieving a dense, dark lash line with minimal weight.

Synthetic Fibers

High-quality synthetic options that are durable, hold their curl well, and are ideal for creating bold and dramatic lash styles. They are also a cost-effective and vegan-friendly choice.

Bio-degradable Fiber

Environmentally friendly, gentle on sensitive skin, lightweight and comfortable, natural appearance, reduces allergic reactions, and appeals to eco-conscious consumers seeking sustainable beauty products.

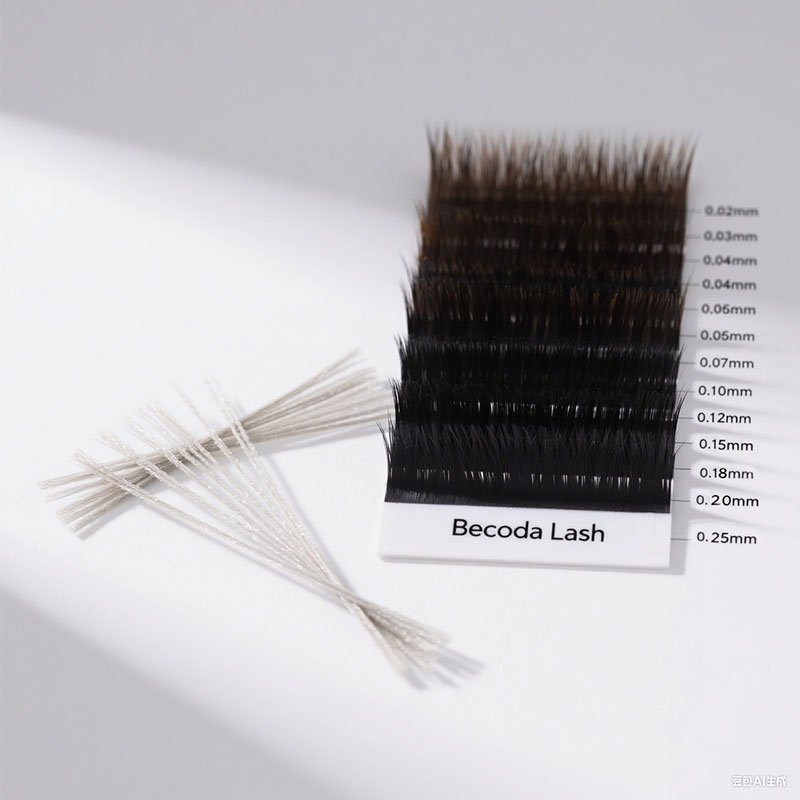

Becoda Lash offers a range of thickness measurements, including 0.02mm 0.03mm 0.04mm 0.05mm 0.06mm 0.07mm 0.10mm 0.12mm 0.15mm 0.18mm 0.20mm 0.25mm .

Thinner fibers (0.03mm–0.07mm) create a natural, delicate look, while thicker fibers (0.10mm–0.25mm) deliver dramatic volume and bold styles. Our advanced manufacturing ensures consistent thickness across every strand for flawless application.

We offer a variety of curl types, including J, B, C, CC, D, L, and M curls, each designed to achieve specific aesthetic effects. J curls provide a subtle lift, while D and CC curls offer dramatic, eye-opening effects. L and M curls are ideal for unique eye shapes, enhancing natural beauty. Our precision curling process ensures long-lasting, uniform curls.

Taper

The gradual thinning of the lash fiber from base to tip, affecting softness.

Retention

The duration a lash extension adheres to the natural lash

Volume Fan

Multiple fine extensions fanned out and applied to a single natural lash.

Heat Bonding

Using heat to fuse fan bases, creating a seamless, glue-free bond.

Hypoallergenic

Materials tested and formulated to minimize the risk of allergic reactions.

Classic Lashing

The application of one single extension to one single natural lash.

Lash Tech: The Art & Science of Lash Production

Our manufacturing process is a symphony of precision engineering and skilled artisanship. We have refined each stage to ensure maximum efficiency, consistency, and quality. Follow the journey from a single fiber to a perfectly finished false eyelash, and learn how our advanced equipment plays a crucial role at every step in Becoda Lash Tech.

Raw Lash Material Quality Assurance

Precision Molding & Shaping

Exact Lash Fiber Trimming

Advanced Curl Setting & Sterilization

Meticulous Packaging Preparation

Comprehensive Final Quality Check

Becoda Lash Tech:Innovation in Lash Production

At Becoda Lash, innovation is at our core. Our dedicated R&D team continuously explores novel fiber compositions for enhanced softness and durability, develops next-generation curling techniques for superior retention, and integrates AI-driven quality control systems for unparalleled precision.

We hold several proprietary patents in lash manufacturing, ensuring our partners always receive cutting-edge products that lead the market in performance and aesthetics. Our commitment to research and development means you're always a step ahead with Becoda Lash.

Uncompromising Quality: Our Commitment to Excellence

At Becoda Lash, excellence isn't just a goal—it's embedded in every step of our manufacturing process. Our multi-layered quality assurance system ensures that each lash meets the highest standards of performance, safety, and aesthetic appeal, delivering consistent results that professionals and consumers trust.

Rigorous Quality Control Measures

Our rigorous fiber inspection protocol ensures exceptional quality through comprehensive testing of all raw materials. We conduct precise dimensional measurements, mechanical property evaluations, chemical resistance testing, and thermal stability assessments. Every batch undergoes visual inspection, tensile strength testing, curl retention analysis, and pH stability verification. For natural fibers, we perform additional sterilization verification and protein integrity assessment. With strict acceptance criteria including ≥45MPa tensile strength for synthetics and zero microbial contamination for natural materials, our multi-point quality control system guarantees consistent, reliable products. Becoda Lash’s commitment to excellence ensures every lash meets the highest industry standards.

The eyelash manufacturing process adheres to rigorous quality control, ensuring consistent product excellence. This involves eight critical stages, each with specific control points to prevent defects and maintain efficiency.

Beginning with Raw Material Quality Control, incoming fibers are meticulously inspected for quality and documented. Style Design and Planning verifies specifications before production. The Fiber Layering Process meticulously checks layer count, thickness, and alignment, with adjustments made for any deviations. Semi-Finished Product Checks ensure basic lash shape and structural integrity. Trimming and Tip Preservation focuses on precise cuts and natural tip appearance. Curve Creation monitors aluminum tube conditions and curve formation. Thermal Processing meticulously controls temperature for styling and sterilization, ensuring shape retention without heat damage. Finally, Tray Placement verifies proper lash positioning and packaging. This comprehensive, stage-by-stage approach guarantees high-quality, defect-free eyelashes.

Before packaging, every lash strip undergoes our comprehensive 12-point inspection protocol. Visual inspection under magnification identifies any defects including color variations, surface imperfections, or curl inconsistencies. Length uniformity is verified using automated measurement systems with ±0.1mm accuracy. Adhesion testing involves controlled application and removal procedures to ensure proper bonding without damage to the lash base. Our quality inspectors also conduct flexibility tests to confirm lashes maintain their shape and resilience after repeated handling. Any products failing these stringent criteria are immediately removed from production lines.

Our advanced batch management system assigns unique identification codes to every production run, enabling complete traceability from raw materials to finished products. Each batch undergoes accelerated aging tests to predict long-term stability and performance. We maintain detailed records including material lot numbers, production parameters, environmental conditions, and quality test results for minimum five years. This comprehensive documentation system enables rapid identification and resolution of any quality issues, ensuring continuous improvement in our manufacturing processes.

Our commitment to quality extends through rigorous internal and external testing protocols that exceed industry standards. Internal testing includes comprehensive biocompatibility assessments using standardized cell culture methods to evaluate potential allergic reactions. Durability testing subjects lashes to simulated 30-day wear cycles, including exposure to makeup removers, cleansers, and environmental conditions. Heat resistance testing ensures lashes maintain their curl and integrity at temperatures up to 60°C, accommodating various styling tools and climate conditions.

External validation comes through partnerships with accredited laboratories that conduct independent testing according to international cosmetic standards. Our products comply with FDA regulations for cosmetic accessories, meeting strict requirements for materials used near the eye area. We maintain ISO 9001:2015 certification for our quality management systems, demonstrating our commitment to consistent quality delivery. Additionally, our bio-degradable materials carry ASTM D6400 certification for compostability, validating their environmental claims. CE marking ensures compliance with European safety standards, while our manufacturing facility adheres to Good Manufacturing Practices (GMP) for cosmetic products.

Partner With a Becoda Lash

Choosing a manufacturing partner is a critical decision. We offer more than just production; we provide a comprehensive partnership built on expertise, technology, and a shared commitment to your brand's success. Discover our wide range of products, our extensive customization capabilities, and the core advantages that make us the ideal choice for your false eyelash needs.

Customization & OEM/ODM Services

Our Wide Product Spectrum

- ✓ Expertise & Experience: Decades of specialized experience with a team of skilled professionals driving our success.

- ✓ Advanced Technology: Continuous investment in cutting-edge equipment for superior efficiency and consistency.

- ✓ Unwavering Quality: A comprehensive quality assurance system that guarantees excellence in every product.

- ✓ Innovation & R&D: A dedicated team constantly exploring new materials and production techniques.

Quanto tempo leva para os cílios crescerem de volta? Table of Contents Imagine isto: você acidentalmente puxou alguns cílios ao remover a máscara, ou talvez suas extensões de cílios tenham deixado seus cílios naturais ralos. Agora você se pergunta: quanto…